Tube Furnaces

Tube furnaces are widely used in heat treatment processes, including annealing, hardening, and tempering of metals and alloys.

These processes involve heating materials to specific temperatures and then cooling them at controlled rates to achieve specific material properties.

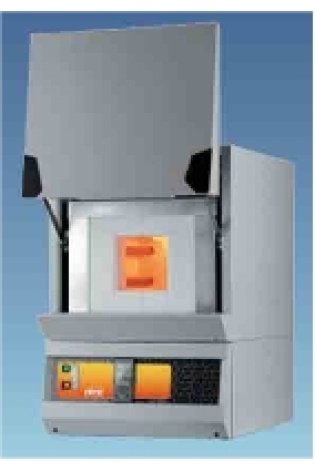

Universal electrical furnaces are designed for the burning of ceramics, stone mass, thermal processing of small metal particles in the ambiance at the maximum temperature of 900°C, 1260°C, and 1340°C.

Chamber size

Dia 60x300mm (can be customised)

Max. temperature

1200 C (<2hour)

1400 C (<2hour)

1700 C (<2hour)

Working temperature

1100 C

1300 C

1600 C

Temperature controlling

PID automatic control via SCR (Silicon Controlled Rectifier) power control with phase angle fired, current limiting resistor.

51 programmable segments for precise control of heating rate, cooling rate and dwell time.

Built in PID Auto-Tune function with overheating & broken thermocouple broken protection.

Over temperature protection and alarm allows for operation without attendant.

Temperature accuracy

±1C

Temperature Uniformity

±5C over 120mm

±3C over 80mm

Heating rate

0-20C /min

Thermocouple

K type

S type

B type

Heating element

Heating wire

SiC heating element

MoSi2 Heating element

Furnace Chamber

2 layers of ceramic fiber insulation

3 layers of ceramic fiber insulation

3 layers of ceramic fiber insulation

1st: 1430°C ceramic fiber board

1st: 1700°C ceramic fiber board

1st : 1800°C ceramic fiber board

2nd: 1260°C ceramic fiber board

2nd:1430°C ceramic fiber board

2nd: 1600°C ceramic fiber board

3rd: 1260°C ceramic fiber board

3rd: 1260°C ceramic fiber board

Furnace structure

Double layer steel casing with dual cooling fan, surface temperature below 60C

Safety

Power cutting off when furnace door open

Working voltage

110V or 220V or 380V, 50HZ or 60HZ

Rated power

2KW

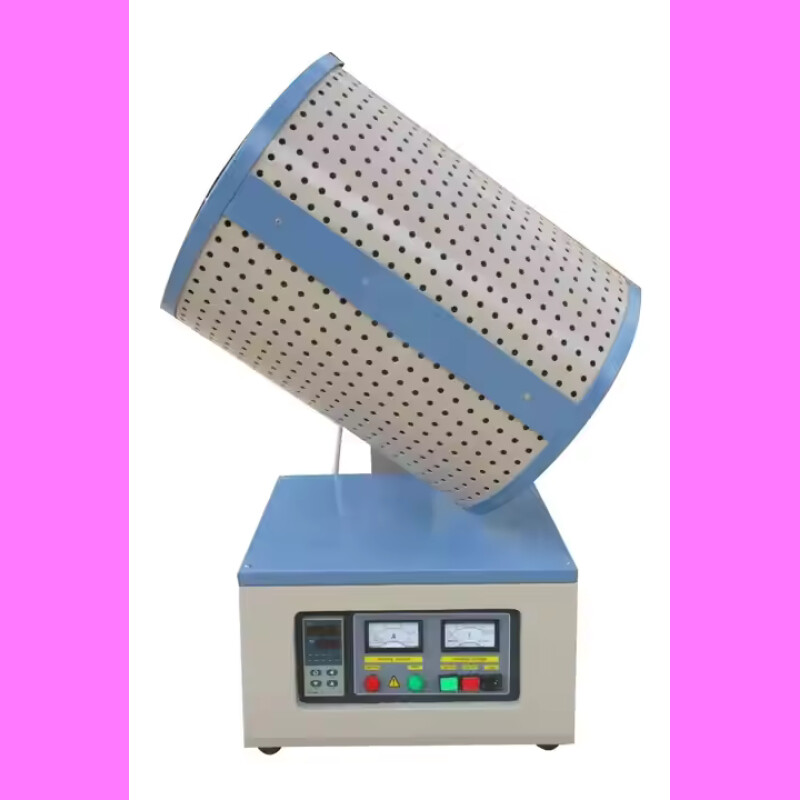

Can be Vertical ?

YES

Can be Rotary? YES

Can be Multi zone? YES

CVD system OPTIONAL

Stander chamber size (mm)

40x300 60x300 80x300 100x300 120x300 150x300

40x450 60x450 80x450 100x450 120x450 150x450

Note: the chamber size can be customized

Tube Furnaces